Researchers in the US and France have developed a electronic touch pad that is based on metallised paper. This could lead to throwaway touch pads potentially incorporated into anything from food packaging to disposable or sterile medical devices.

The touch pads are made from paper coated in a layer of aluminium around 10nm thick. The paper is then overlaid with a thin film of transparent polymer. The paper the touch pads are based on is already produced commercially and is used for everything from labels on beer bottles to glossy book covers. It is therefore very inexpensive and cost only around $0.25/m2 to manufacture.

Since the paper is so thin two surfaces of the thin metal film can be easily placed in proximity to each other, leaving a small gap between them. This making up the essential elements of a standard capacitor. The research team have come up with two types of configurations of capacitor. One requires two sheets of the paper to be stuck together, with a ‘horizontal’ gap between the metal surfaces; the other uses only a single sheet, with a ‘vertical’ gap cut through the conducting surface.

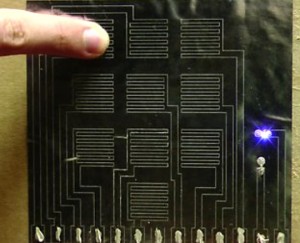

“We use a laser cutter to ablate through the conductive layer to create distinct regions of conductivity on the metallised paper”, said lead researcher Aaron Mazzeo, who works in the lab of George Whitesides at Harvard University, US. Using the laser it is possible to cut a number of individual capacitors within the surface, each corresponding to a key on the pad. The keys are then linked to an external source of power and to electronic circuitry to detect when a given key is touched.

Just like with capacitive touch screens used on many mobile devices today, the human body itself acts as a capacitor. When a finger touches an area on the screen, or in this case one of the keys, there is an increase in capacitance at the key detected by the external electronics. “We are interested in designing systems that use low cost materials to provide high-tech functionality”, said Mazzeo. The paper touch pad will really come into its own when the power source and associated electronics also become cheap, flexible and disposable. There is how ever still areas where this type of technology could be used already. As an example security on packaging or to incorporate touch pads in sterile or contaminated medical environments.